Meet the Supplier Day is an opportunity for OECM customers to go beyond the contract and connect directly with awarded supplier partners to explore best practices, innovations, and training opportunities that strengthen operations across Ontario’s public and broader public sector.

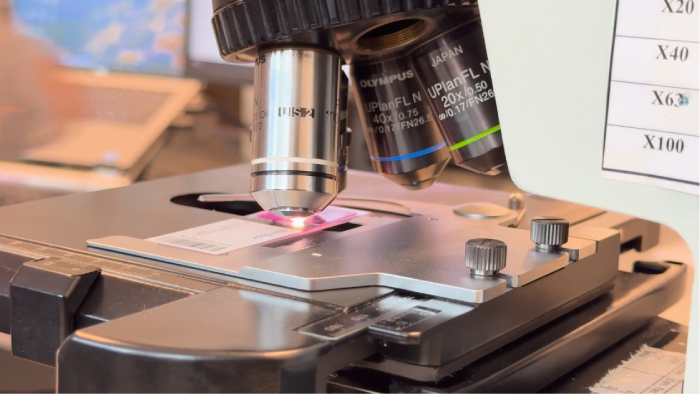

Last month, OECM customers joined Pinchin Ltd., one of the awarded supplier partners on OECM’s Environmental Professional Services and Roofing Consulting Services agreements, for our first Meet the Supplier Day – a two-part education session and a guided tour of Pinchin’s Asbestos and Microbiology Labs.

After a warm welcome and introduction from Stephen Booth, EVP of GTA Indoor Environmental Quality at Pinchin, OECM Category Manager Ronald Wai opened the day with a brief overview of OECM and the simple steps to leverage our agreements.

The morning focused on roofing and hazardous materials. The afternoon moved into the lab to see how Pinchin analyzes asbestos, mould, bacteria (including Legionella), and more, and how their training programs support safe, compliant work across Ontario’s public and broader public sector.

Education Session: Roofing Strategy & Asset Management

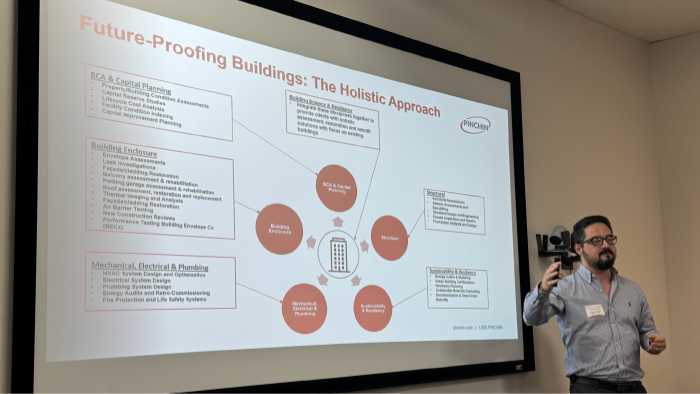

Speaker: Steve LaPointe, P.Eng., Operations Manager, Building Enclosure Services, Building Science & Resiliency

Key Takeaways:

- A holistic approach to building science – a roof is one component that must tie into units, windows, walls, and air barriers.

- Avoid the “out of sight, out of mind” trap – treat the roof as an asset, not a liability.

- Replacement costs have surged – nearly 2 – 2.5 times since 2019 – so plan proactively.

- There is no silver bullet – each building and even each roof area needs the right system and details.

- Typical failures: blisters, open seams, ponding, vegetation, failed flashings (often linked to poor detailing), value engineering, installation errors, lack of Quality Assurance (QA), and deferred maintenance.

- Use third-party QA and diagnostics (for example, infrared and wind uplift testing) – think 1-10-100 rule (it cost $1 to prevent a problem in design, $10 to fix it during the process, and $100 to fix it after it fails), and catch it in design, not after failure.

- Manage the asset over time – plan 1, 3, 5, and 10 years, phase work, tackle the worst area first, and boost R value to reduce energy costs.

The cheapest fix for a roof is the one you make on paper – catch it in design, not after failure.

Education Session: Hazardous Materials

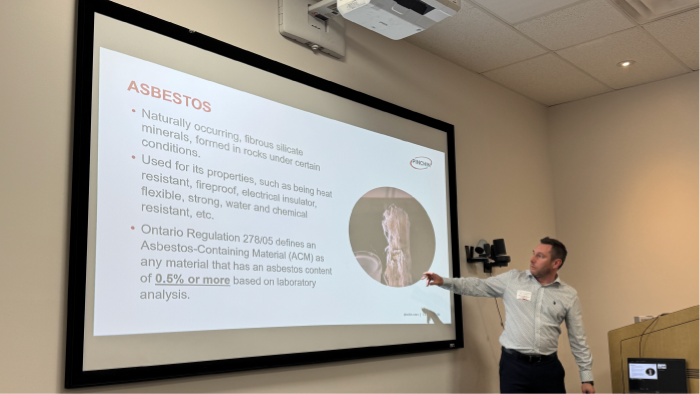

Speaker: Michael Barana, Operations Manager (London), Hazardous Materials

Key Takeaway:

- How environmental risks intersect with roofing and which hazardous materials get overlooked.

- The database keeps growing – Pinchin is finding asbestos in more materials than 30 years ago as data improves.

- In Ontario, an asbestos containing material is ≥ 0.5% by dry weight.

- Non-friable products (for example, caulking and tars) were still used up to December 30, 2018 – new roofs can sit over older asbestos roofs, so cores and interior checks matter.

- Vermiculite (Libby, Montana): Pinchin’s lab identifies origin rather than reporting a percentage – fines settle, and disturbance can drive airborne fibres above limits even when bulk reads low.

- Polychlorinated Biphenyls (PCBs) show up in caulking and paints, and disposal requires destruction by incineration. Fluorescent light ballasts must be removed by December 31, 2025.

- A management survey is non-intrusive and not sufficient for construction – the design stage is the time for a designated substances survey, coordinated across trades.

- Overlooked conditions on roofing projects: residual asbestos tars on metal decking, vibration “snowing” fireproofing, fasteners penetrating interiors, insulated roof drains, flaking lead paint – plan protection and any needed air monitoring, and keep everyone on the same page.

Asbestos risk in roofing isn’t just the membrane – it’s the tars, caulking, and the old layers you only find when you core.

Training that fits your team

Pinchin offers a wide range of courses for you and your team which is available at many of Pinchin’s offices, at a local venue, or even at your place of business.

View all Pinchin’s Upcoming Courses

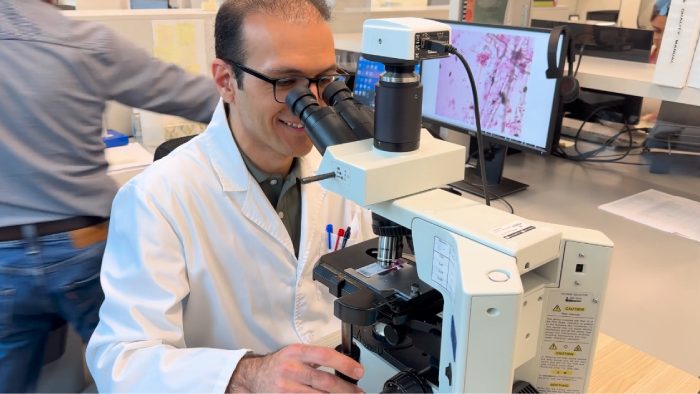

Lab Tour: Pinchin’s Asbestos and Microbiology Labs

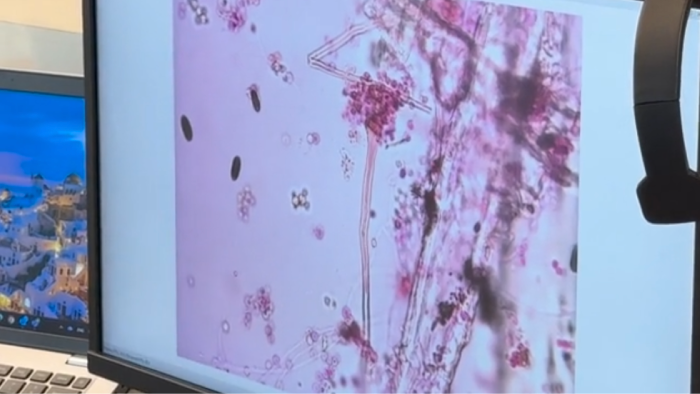

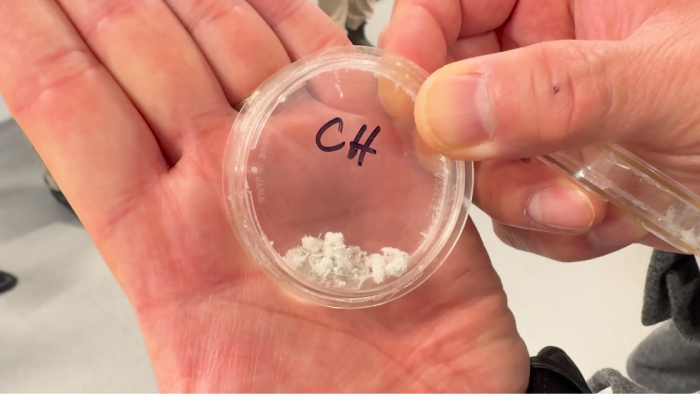

In the afternoon, we moved over to the lab for a guided walk through Pinchin’s Asbestos and Environmental Microbiology Laboratories. The tour followed the full path of a sample – intake and chain of custody, preparation and microscopy, culture and PCR rooms, and final review and reporting – so participants could see how defensible results are produced.

In the microbiology areas, technicians showed how they assess fungi and mould, searching for diagnostic structures under the microscope – a light hearted “God particle” moment when the key feature comes into focus.

We also saw how the laboratory scales during investigations, and when PCR (Polymerase Chain Reaction) is used for time sensitive targets such as Legionella. In the asbestos lab, the team explained methods, rush options, and why analyst training and workload limits are central to data quality.

Key highlights from the tour:

- Asbestos program: Operating since 1986, with rush options from 24 hours to one week, and deliberate limits on analyst throughput to preserve accuracy.

- Training and competency: New lab staff train about 6 months before certain preparation tasks and about 1 year before analyzing independently – a long runway that supports consistent methods and QA.

- Throughput when needed: Microbiology can process about 2,000 culture plates per day during intensive campaigns, with surge controls to maintain quality.

- PCR speed to decision: Same day PCR is available for time critical screening such as Legionella, helping facilities reopen systems and spaces sooner.

- What microbiologists look for: Typical morphologies include white fluffy colonies – as well as brown and blue variants – followed by confirmation as needed.

- Quality over speed: Analysts in the asbestos lab handle up to about 40 samples per day so each read remains careful and defensible.

- Field sampling tips: For bulk or settled material, 1 to 2 cups are typically adequate, and representative samples, clean tools, and clear labelling support faster, cleaner analyses.

For many participants, seeing Pinchin’s laboratories in action helped bridge the gap between procurement and practice, demonstrating how defensible results, rapid PCR options, and disciplined QA translate into safer decisions, fewer delays, and compliant projects for OECM customers.

Interested in Hosting Tour or Event for OECM Customers?

OECM customers are always eager to learn more about our supplier partners and OEMs. If you are a supplier partner or OEM in one of our agreements and would like to host an OECM tour or event, please reach out to your Supplier Relationship Manager.